- Tecnomatix plant simulation manage class library how to#

- Tecnomatix plant simulation manage class library software#

- Tecnomatix plant simulation manage class library series#

Many also are coming from lean and agile mindsets and are used to thinking about how to improve their operations.” “Manufacturing is our biggest industry, and the typical users are people with backgrounds and education in industrial and systems engineering, with many holding degrees in that field. “Our emphasis has been from the start on 3D simulations with realistic and stunning graphics to solve modern manufacturing problems,” said Markus Cueva, educational program director for the 18-year old firm.

Tecnomatix plant simulation manage class library software#

“Once you do that, creating a simulation comes pretty quickly,” he said.įlexSim, an independent company offering a software package of the same name offers another simulation tool for factory simulation. If we are modeling how a part is created through a welding process, we look at the statistical variability around that step and use that to understand the variability in the entire process.”įor maximum utility, Kranz encourages users to build a functional specification of the process to define the objective and describe the system and rules of operation, with special consideration for the data required.

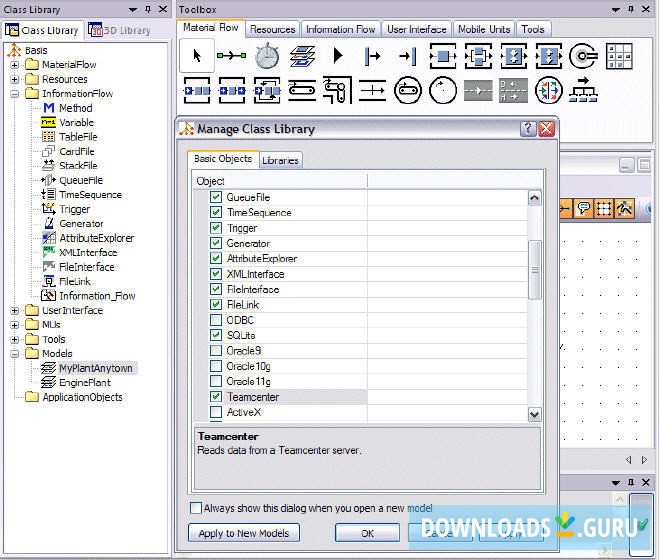

“For example, we do not model the thermodynamics or physical properties of the system. “ really provide value by characterizing and understanding the variability that exists in a system,” he said. When asked about accuracy and potential error, Kranz re-directed the question into a discussion of how exactly these kinds of simulations offer value. Users can also create customized templates. The source of the data is an extensive library of common data objects-think a conveyor belt or packaging machine selectable from a menu. Automotive OEMs and small-part manufacturers at the sub-tier level use it, as well, to understand and modify their processes. Supply-chain analysis and human resource planning are common uses of the Arena technology, he said. “A variety of industries use our software, with manufacturing clearly number one,” Kranz said, noting that more than 52,000 college students worldwide have downloaded the software. These SIM tools can also be used to map out and simulate business processes, as well, by using the same flow-chart technique. Manufacturing simulation tools are well suited for companies that are struggling with at least one of three challenges, he said: A high degree of uncertainty or variability constraints on resources, or highly complex manufacturing systems. Easy-to-navigate user interfaces, with familiar drag-and-drop components from pre-loaded libraries, are essential elements of today’s digital manufacturing simulations.

It can display results in either a 2D or 3D format, employing a gaming engine to produce its 3D graphics. “We use a flow chart technique that looks a lot like flow charting tools, so you build up to the workflow and process, visually adding in information with mouse clicks that avoids programming,” Kranz said, explaining the key to making Arena’s simulations easy to create and use.

Tecnomatix plant simulation manage class library series#

Discrete event modeling depicts the behavior of a complex system as a series of well-defined and ordered events. “We believe strongly that engineers should be spending their time solving important problems for their organization and not being programmers,” said Robert Kranz, director and general manager for the Arena business of Rockwell Automation.Īrena was one of the pioneers in discrete event simulation applied to manufacturing. New data sources, such as from the Industrial Internet of Things and 3D scanners, allow higher fidelity and accuracy in factory simulations.Įasy-to-use factory simulations are a key to wider adoption. Increasingly, the factory systems used to create them are doing likewise.ĭigital manufacturing’s rise will become ever more prevalent as computing gets more and more powerful. From CAD designs to sophisticated simulations used to verify their functionality, products as complex as airplanes and automobiles live their early conceptual lives in a digital world. A significant trend in the last decade in manufacturing and engineering can be summed up in a simple phrase-more digital.

0 kommentar(er)

0 kommentar(er)